Research and development of flexible laser welding/cutting/processing system

Based on the intelligent laser welding system integration of high-precision industrial welding robot and laser with high beam quality, the welding process visualization, real-time parameter detection and intelligent control system can be developed to realize the welding of three-dimensional complex workpiece.

Research features:

1. Based on industrial robots, the development includes high-power laser cutting, laser wire filling welding, laser arc composite welding, laser vacuum welding, double-beam double-robot welding system, laser cladding, laser cleaning and other systems;

2. With the robot as the core, it completes the communication with the laser and the wire feeder, and combines the robot off-line programming technology to realize flexible movement according to the prefabricated model and path; Fully consider the safety of equipment operation, and realize function selection and emergency treatment in combination with switching power supply, button and miniature circuit breaker.

3. 3D laser welding process development: Develop intelligent laser welding processes for 3D curved workpiece.

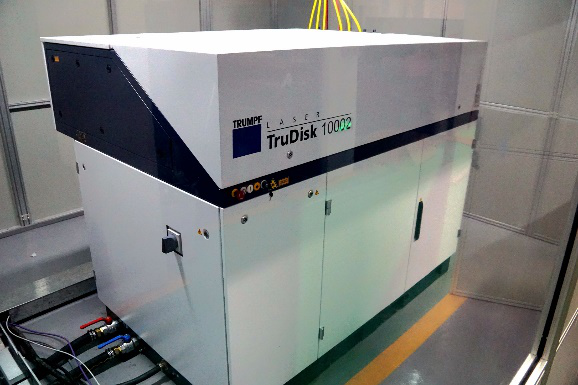

10kW disc laser

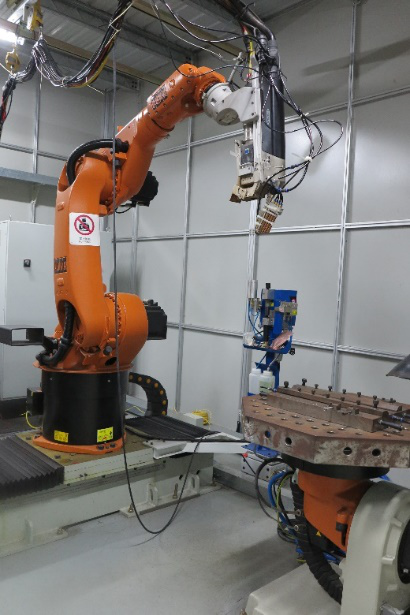

Vacuum welding system

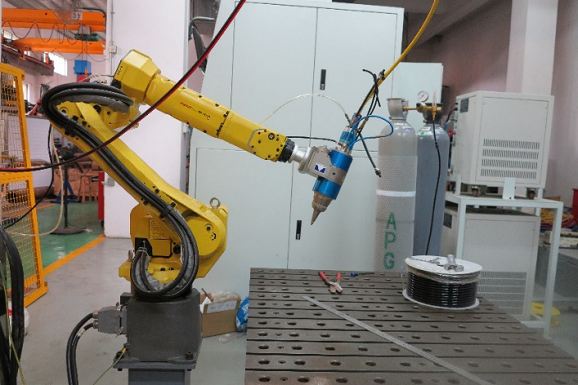

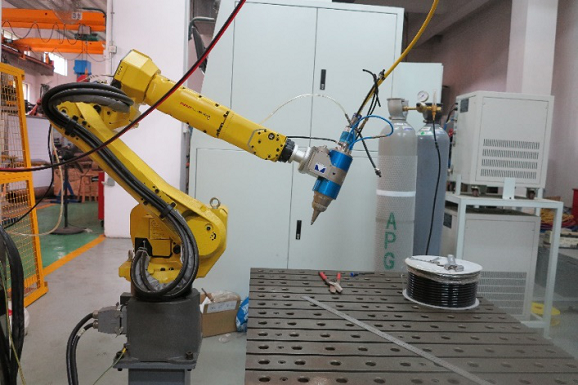

High power laser cutting system

Laser-MIG hybrid welding system