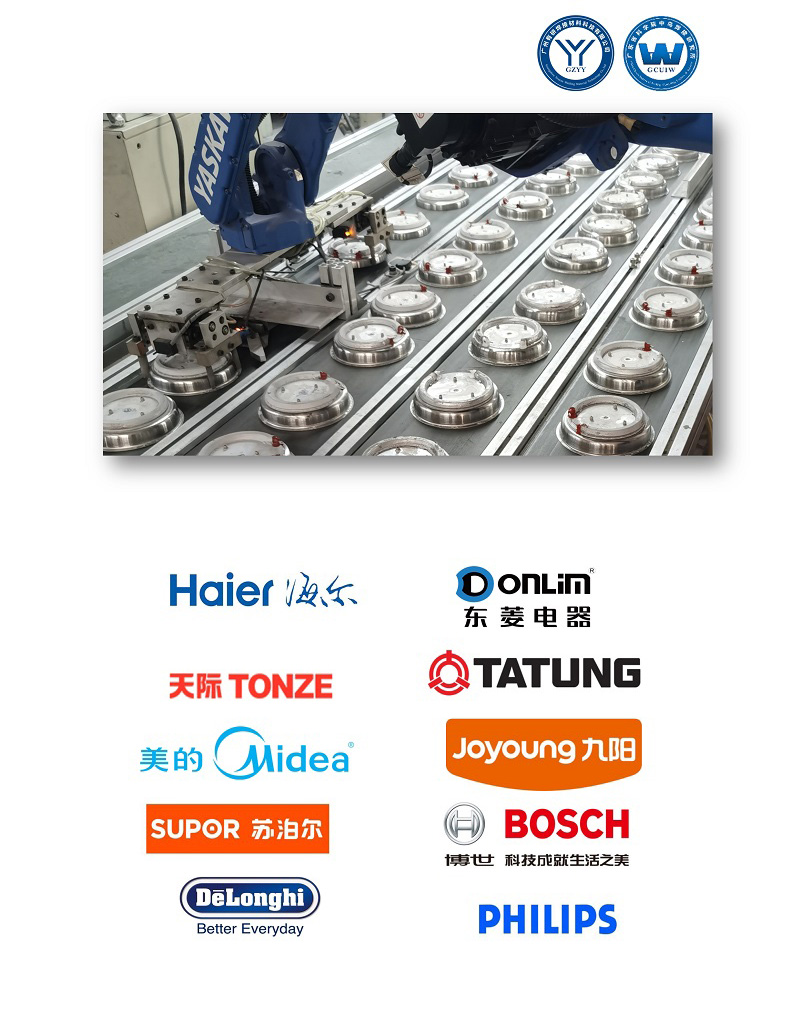

Electric small household appliances are mainly composed of the pot body, base, temperature controller and heating plate components.

The pot body, base and temperature controller have realized intelligent production; However, the intelligent production of heating plate components has not been realized, resulting in the fracture of the entire intelligent production chain of electric kettle.

There are two main reasons for this:

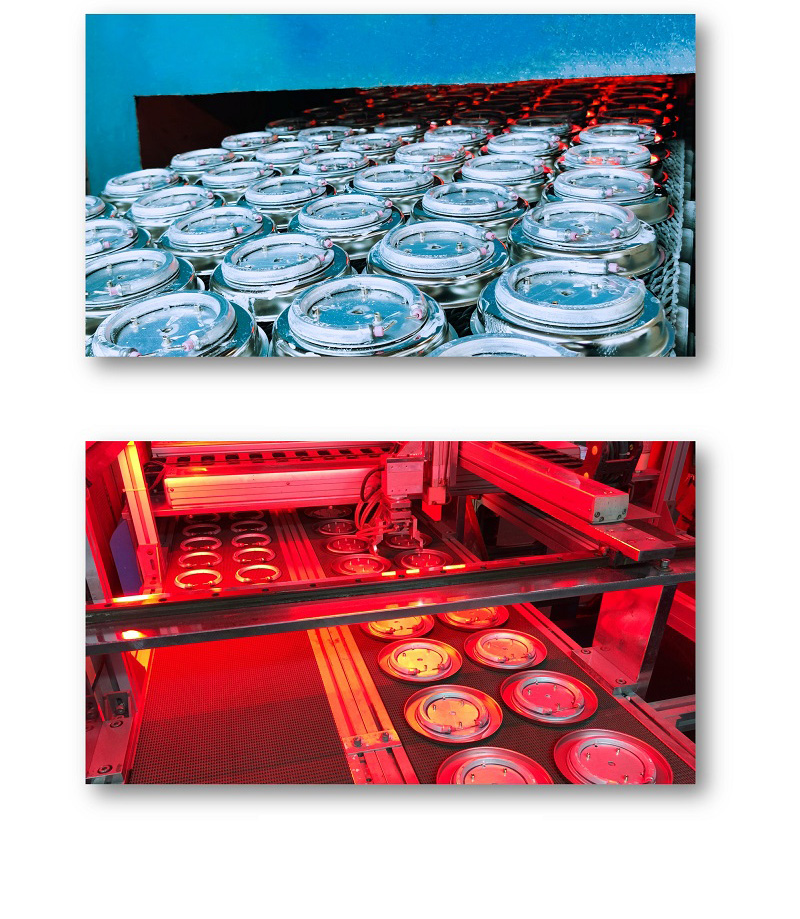

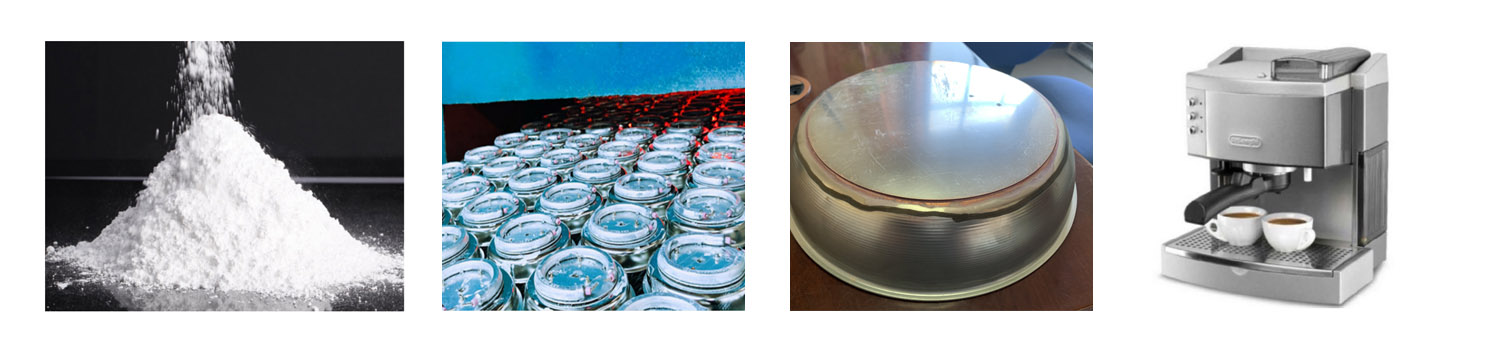

1) The structure of the heating plate assembly is relatively complex. It is composed of aluminum alloy heating tube, pure aluminum plate and stainless steel disc in turn. The metallurgical connection between the three parts needs to be completed through brazing. The design requirements for intelligent operation are relatively high.

2) The materials used for brazing are powdery aluminum flux and powdery aluminum solder, which are the key factors in the restriction.

The reasons are as follows:

① Because it is powdery, the manipulator cannot accurately and quantitatively clamp, so the cloth distribution process can only be manually screened;

② Due to its powdery shape, the adhesion of solder on the workpiece is small, and the rolling friction between the workpiece is easy to form, resulting in the frequent scattering of solder and the displacement and dislocation of the workpiece in the process of movement and transportation, which seriously affects the brazing quality, so it can only be operated with manual care, resulting in low production efficiency and high labor costs.

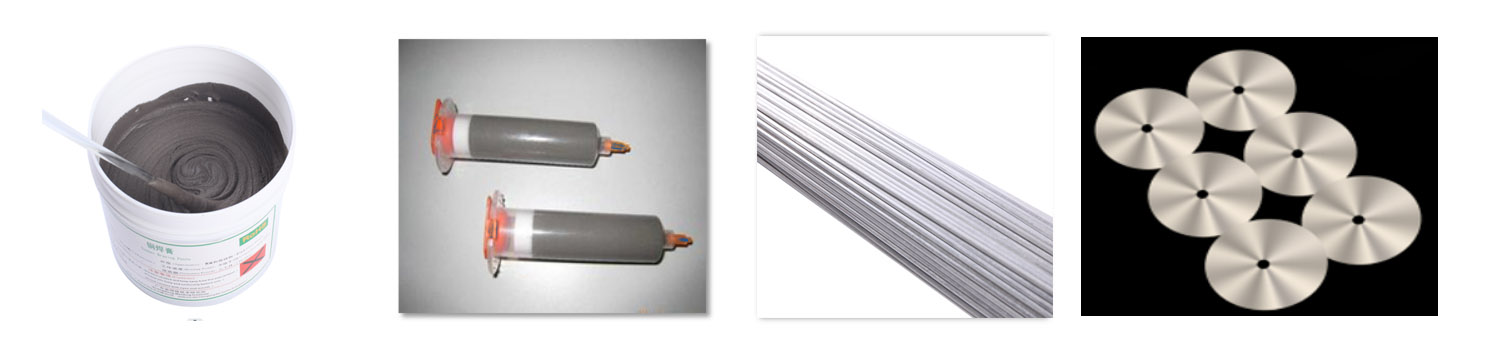

By developing new brazing materials that can realize intelligent feeding and green production - aluminum solder, aluminum solder paste and composite aluminum solder wire, our company replaces the original powder aluminum solder and aluminum solder, assists in the development of peripheral automation equipment, realizes the automatic distribution, assembly and welding of heating plate components, and lays the foundation for the automatic green production of electric kettle.

In the electric heating appliance industry, it mainly involves the welding of heating tubes and heating plates. The base metal is aluminum, copper or stainless steel. The corresponding brazing materials are powdered aluminum flux, aluminum solder, aluminum solder paste, copper solder paste and nickel solder paste. The brazing processes include high-frequency induction pressure brazing and protective atmosphere tunnel furnace brazing. The application manufacturers include: Mitsubishi Group, Baker Electric Heating Technology (Shenzhen) Co., Ltd., Midea Group, Zhongshan Ampel Electric Appliance Co., Ltd Hangzhou Redway Electric Heating Technology Co., Ltd., Changzhou Simate Electric Appliance Co., Ltd., etc.