Special fund of the scientific research institute of the Ministry of Science and Technology of the People's Republic of China "Research on the application of high-quality automatic brazing series solder paste preparation technology".

The multiform product types, such as powder, paste, wire and sheet, meet the requirements for brazing and assembly of various complex workpieces, and are applicable to different brazing processes such as flame welding, high-frequency induction brazing and shielded atmosphere furnace welding. Over the years, the in-depth research and development and application of new materials and new processes have led to the continuous improvement of brazing technology in the industry, promoting the transformation and upgrading of industrial manufacturing technology to intelligent and green.

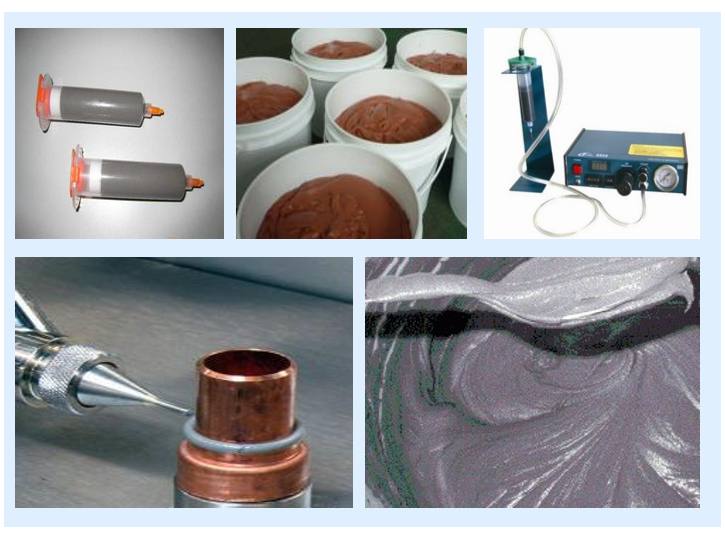

Mainly used in: paste solder product line

Paste solder products are a new type of welding materials independently developed on the basis of powder solder through interdisciplinary research. It has a wide range of applications and simple operation process, and can replace powder or solid solder in many fields. Its research and development cycle is long, its technology content is high, and its manufacturing process is complex, which plays a key role in the enterprise's automatic production.

01. Aluminum base paste series brazing materials

● Aluminum paste: LHG-1 to 8, WLHG-A/B/C

● Copper based paste: THG-A/B, THG-1

● Process and scope: protective atmosphere furnace welding, aluminum-aluminum alloy, aluminum-stainless steel, iron tube-iron alloy plate, stainless steel sheet, copper-copper alloy, iron, stainless steel, hydrophilic paste can be adjusted with water in a certain proportion.

● Product features: It is suitable for brazing the surrounding pipe with complex welding structure, with good wettability, good weldability, bright and full welding spot, and high welding reliability.

02. Nickel base paste series brazing materials

● Nickel base paste: NHG-1/2 ZWNHG-1/2

● Process and scope: furnace welding in protective atmosphere, vacuum welding, stainless steel - stainless steel welding, low melting point, good fluidity

● Product features: suitable for the welding of complex stainless steel heating pipes, jewelry and watch bands, with low melting point, good fluidity, and fine and smooth paste.

● Needle tip can be used for feeding, and the material has excellent welding performance.

03. Powder series brazing materials (flux)

● FA -, FB -, FS - series

● Process and scope: high-frequency welding, furnace welding, vacuum brazing, welding stainless steel (aluminum) - aluminum, stainless steel (copper) - copper, stainless steel - stainless steel, aluminum alloy (including magnesium) - aluminum alloy (including magnesium), aluminum - copper

● Product features: It is welded with corresponding filler metal, with good wettability, good weldability, bright and full solder joint, and high welding reliability.

Our different series of high-quality brazing materials are mainly used in the brazing of the same or different metals such as aluminum (aluminum alloy) - aluminum alloy, aluminum (aluminum alloy) - stainless steel, copper copper alloy, copper stainless steel, stainless steel - stainless steel, and other industries such as kitchenware, hardware, electric heating appliances, automobiles, and power station air cooling. Its materials and technology have been granted multiple authorized patents, and has been awarded provincial and ministerial awards for many times. Its product quality is at the advanced domestic or international level.

1. In the new energy (conventional energy) automotive heat exchanger, power station heat exchanger, electric sports, communication industry, GPU, 5G base station and other heat exchanger components, mainly involving various aluminum, copper conventional and microchannel heat exchangers or copper aluminum pipe joint welding, application manufacturers such as: Zhejiang Jinhecheng Co., Ltd., Yinlun Co., Ltd., Foshan Nanhai Leite Auto Parts Co., Ltd., Yingneng Electric Cooling (China) Co., Ltd Lixun Heat Transfer Technology (Huizhou) Co., Ltd., Huizhou Wurong Hardware Electronics Co., Ltd., etc.

2. In the electric heating appliance industry, it mainly involves the welding of heating tubes and heating plates. The base material is aluminum, copper, or stainless steel, and the corresponding brazing materials are powdered aluminum solder, aluminum solder, aluminum solder paste, copper solder, and nickel solder paste. The brazing processes include high-frequency induction pressure brazing and protective atmosphere tunnel furnace brazing. Application manufacturers include: Dongling Group, Baker Electric Heating Technology (Shenzhen) Co., Ltd., Midea Group, Zhongshan Ampel Electric Appliance Co., Ltd Hangzhou Rewei Electric Heating Technology Co., Ltd., Changzhou Ximate Electric Appliance Co., Ltd., etc.

3. In the hardware and kitchenware industry, it mainly involves the brazing of three or multi-layer double bottom pots such as stainless steel, aluminum or copper plates. Application manufacturers such as: Guangdong Baoding Stainless Steel Products Co., Ltd., Lingfeng Group, Jiangmen Honghua Metal Products Co., Ltd., Xinhui Rixing Stainless Steel Products Co., Ltd., Huizhou Hongli Hardware and Plastic Products Factory Co., Ltd.