Product detailsParametersProcessApplication

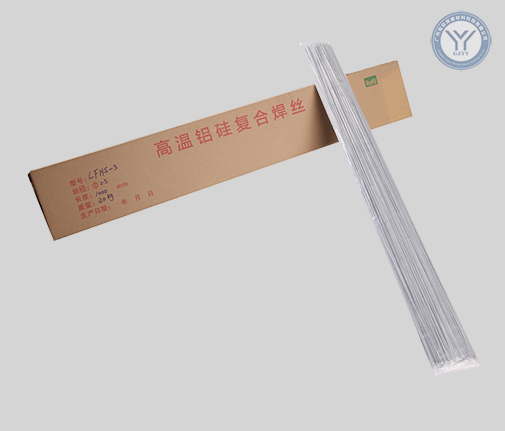

Model: LFHS-2

Suitable process and application: flame welding, aluminium-aluminum alloy, better fluidity than LFHS-3 during welding

Composition: Al: 61.4~91.l; Si:7.7~12.6; F:5.1~15.7; K:Bal; other

Appearance and specification: silver gray straight wire or rolled wire, Φ 1.6、 Φ 2.0、 Φ two point five

Melting point (melting range): 558-585 ℃

Al:

| 61.4~91 |

Si:

| 7.7~12.6 |

| F: | 5.1~15.7 |

K:

| Bal |

| Other | |

Brazing temperature: 558-585 ℃

Applicable process: flame welding, aluminum-aluminum alloy, with better fluidity than LFHS-3

Aluminum base composite welding wire is an upgraded version of aluminum base flux-cored welding wire; Our company adopts advanced powder metallurgy synthesis method to prepare it, which has the function of self-brazing, without adding additional flux to assist welding, and is green and efficient; Compared with flux-cored process, the welding effect is more uniform and reliable; It is widely used in manual flame welding and automatic flame welding of air conditioners, automobile water tanks, heat exchangers, etc.